Production

What we do

Manufacturing process

Water jet cutting

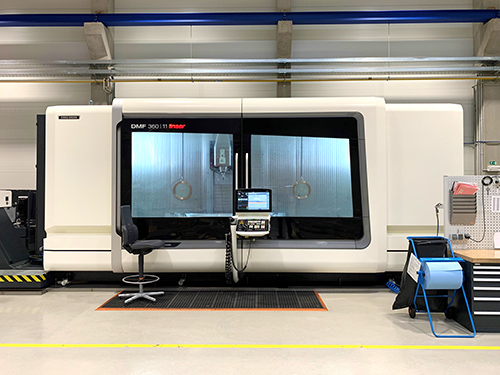

CNC machining and assembly

Manual completion of final assemblies

ATC SPACE s.r.o.

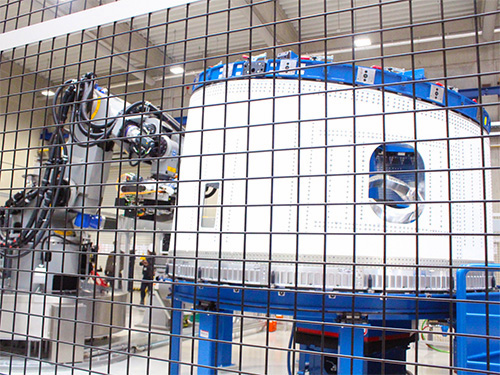

ATC SPACE s.r.o. participates in the production of the new generation of the European rocket Ariane 6. We supply parts and assemblies of aluminium alloys for the launch vehicle and its booster engines.

Each supplied aluminium plate has its own serial number and the appropriate certificate of origin of the material. The certificate states the detailed chemical composition from the analysis of the alloy used. Every product must have a documented history from the basic material to the final part or product. Determining what material the part was made of, when it was made, who made it and what production operations the part went through permeates the entire production.

Subsequently, the products are sent to non-destructive testing and electrochemical surface treatment, so-called anodizing. The aluminium surface is coated with an even, compact oxide layer, which is significantly harder and more chemically resistant than the metal itself. A portion of the milled parts is then shipped to the customer, who assembles them into segments of the main rocket Ariane 6, while the remaining parts are assembled into skirts at ATC Space.

To safely and reliably transport the assembled segments abroad, we use unique containers custom-made for ATC Space, which are placed on an atypical, tailor-made semi-trailer. Individual milled parts and assembled segments are sent to the customer, MT Aerospace in Augsburg.

Machinery

Technical specification

Contact us

ATC SPACE s.r.o.

Schiffauerova 940

339 01, Klatovy – Klatovy II

Czech Republic